Dual clutch transmission offers a unique approach to power delivery, striking a balance between the smooth operation of an automatic and the responsiveness of a manual transmission. This technology, increasingly prevalent in high-performance vehicles, is a fascinating blend of engineering ingenuity and driving experience. Understanding its components, advantages, and disadvantages is crucial for anyone interested in automotive engineering or seeking a more dynamic driving experience.

The design and construction of dual clutch transmissions are quite intricate, but their fundamental operating principles are rooted in efficiently managing power delivery. This allows for rapid gear changes, minimizing the disruption felt by the driver. The precise control over power delivery makes dual clutch transmissions a compelling option for vehicles seeking a combination of efficiency and performance.

Overview of Dual Clutch Transmission (DCT)

A dual-clutch transmission (DCT) is an advanced type of automatic transmission designed to improve fuel efficiency and performance. DCTs use two clutches, one for each set of gears, enabling smoother gear changes and quicker acceleration. This technology has become increasingly popular in automobiles, offering a compelling alternative to traditional automatic transmissions.

Fundamental Operating Principles

DCTs operate by utilizing two separate clutches, each controlling a different set of gears. This allows for seamless gear shifting without interrupting power delivery. When changing gears, the clutch for the outgoing gear disengages, while the clutch for the incoming gear engages, simultaneously transferring power smoothly. This continuous flow of power contributes to a more refined driving experience and enhanced performance.

Key Components and Functions

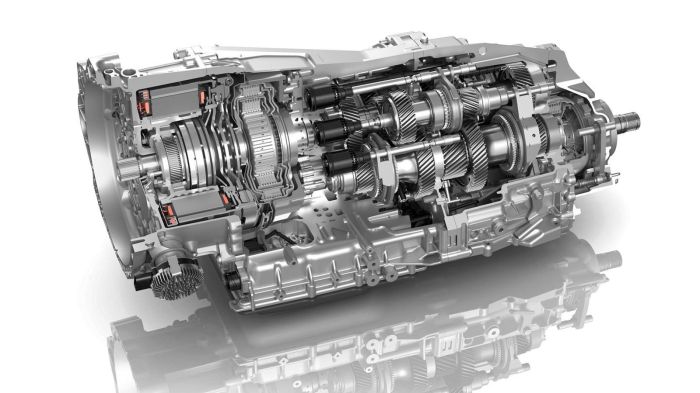

The core components of a DCT system include two clutches, a dual-shaft gearbox with multiple gear sets, and a sophisticated control unit. Each clutch is responsible for engaging and disengaging power to a particular set of gears. The dual-shaft gearbox ensures that both sets of gears are always prepared for the next gear change, enabling quick and precise shifts.

The control unit monitors various parameters, such as engine speed, vehicle speed, and driver input, to orchestrate the optimal gear selection and shifting process.

DCT vs. Traditional Automatic Transmission

A key differentiator between DCTs and traditional automatic transmissions lies in their gear shifting mechanism. Traditional automatic transmissions typically use a single clutch and a torque converter, resulting in a somewhat less immediate power transfer during gear changes. DCTs, with their two clutches, offer a more immediate transition between gears, leading to quicker acceleration and a more responsive driving experience.

This difference in shift timing is particularly noticeable during spirited driving.

Historical Evolution

The development of DCT technology has spanned several decades, with significant advancements in clutch design, control systems, and manufacturing processes. Early DCT prototypes were complex and expensive, but continuous refinement has led to more efficient and affordable designs. The introduction of DCTs in mass-market vehicles has been gradual, reflecting the need to overcome challenges in reliability and cost. Modern DCTs are highly reliable and increasingly common in various vehicle segments, showcasing the progression of automotive technology.

Advantages and Disadvantages of DCT

Dual-clutch transmissions (DCTs) have gained popularity in recent years, offering a compelling blend of performance and efficiency. They excel in specific driving scenarios, but also come with their own set of limitations. This section delves into the strengths and weaknesses of DCTs, comparing them to other transmission types and analyzing their impact on fuel economy and performance.DCTs are designed to optimize gear shifting, leading to smoother transitions and quicker acceleration compared to traditional automatic transmissions.

However, they are not without their drawbacks, and understanding these trade-offs is crucial for informed purchasing decisions.

Advantages of DCTs

DCTs offer several compelling advantages over other transmission types. Their sophisticated gear shifting mechanism allows for quicker and smoother transitions between gears, translating into a noticeable improvement in acceleration and responsiveness. This characteristic is particularly beneficial in performance-oriented vehicles and everyday driving. The rapid gear changes minimize interruption in power delivery, contributing to a more engaging driving experience.

- Enhanced Performance: The rapid shifting capabilities of DCTs allow for quicker acceleration compared to conventional automatic transmissions. This translates to quicker responsiveness in acceleration and overall performance. This feature is especially beneficial in vehicles demanding high performance, such as sports cars or high-performance SUVs.

- Improved Fuel Efficiency (in some cases): While not always demonstrably superior, DCTs can achieve comparable or slightly better fuel economy compared to other automatic transmissions, particularly when operated in a fuel-efficient manner. Modern DCT designs often incorporate optimized shifting strategies that minimize fuel consumption, but this advantage is not always universal and depends on factors such as vehicle design and driving conditions.

- Reduced Emissions: Improved fuel efficiency inherently leads to reduced emissions. DCTs, in instances where fuel efficiency is improved, also contribute to lower emissions, aligning with environmental concerns.

Disadvantages of DCTs

DCTs, despite their advantages, present certain drawbacks. One significant issue is their inherent complexity. The additional components and mechanisms increase the cost of manufacturing, potentially leading to a higher purchase price compared to traditional transmissions. The complexity also contributes to potential maintenance costs and the need for more specialized expertise in repair.

- Higher Maintenance Costs: The intricate design of DCTs necessitates specialized expertise for maintenance and repair. This can lead to higher repair costs compared to conventional automatic transmissions, especially for complex issues. This is largely due to the specific components and procedures involved in maintaining the clutches and other internal mechanisms.

- Potential for Harsh Shifting: While modern DCTs have improved significantly, some drivers still report experiencing harsh or jerky shifts, particularly under heavy acceleration or deceleration. The characteristics of the DCT can vary, with some models exhibiting smoother operation than others.

- Not Always the Most Economical: While DCTs can potentially offer comparable or slightly better fuel economy in some scenarios, this advantage is not consistently observed across all models and driving conditions. The fuel efficiency of a DCT depends heavily on the vehicle design, driving style, and specific DCT implementation.

Fuel Efficiency Comparison

Fuel efficiency comparisons between DCTs and other transmissions are complex. Factors like vehicle design, driving style, and environmental conditions influence fuel consumption. While DCTs are often advertised as fuel-efficient, they are not consistently superior to other automatic transmissions.

Dual clutch transmissions, while offering smoother gear changes in cars, present a unique set of challenges for motorcycle riders. Proper handling of the dual clutch mechanism is crucial for a smooth ride, but rider focus on the shifting process could compromise motorcycle safety, especially in tricky situations. Maintaining a keen awareness of the environment and adhering to safety protocols like those outlined in motorcycle safety guidelines is paramount for any rider, regardless of the transmission type.

Ultimately, a rider’s focus on motorcycle safety should always outweigh the technical aspects of the dual clutch transmission.

Performance Characteristics

DCTs excel in providing rapid acceleration and responsiveness. The quick gear changes translate into a more engaging driving experience, making them a popular choice for performance-oriented vehicles. However, their responsiveness is not always the primary differentiator compared to other transmission types.

Maintenance Requirements

DCTs require specific maintenance procedures. This includes regular fluid checks and replacements, as well as monitoring for potential issues like clutch slippage or gear misalignment. Specialized knowledge and tools may be needed for proper maintenance, potentially increasing the cost of maintenance compared to conventional transmissions.

Applications of DCT in Different Vehicles

Dual-clutch transmissions (DCTs) have gained popularity across a wide range of vehicles, offering a unique blend of performance and efficiency. Their ability to seamlessly shift gears while maintaining a smooth driving experience makes them suitable for various applications, from the high-performance demands of sports cars to the fuel-efficiency needs of economy vehicles. This section explores the specific applications of DCTs, highlighting the diverse ways they enhance vehicle performance and the factors influencing their selection.

Vehicle Types Commonly Using DCTs

DCTs are prevalent in a variety of vehicles, showcasing their adaptability to different driving needs. They are particularly well-suited for vehicles requiring quick and responsive shifting, but also demonstrate benefits in terms of fuel efficiency.

- Sports Cars: DCTs excel in high-performance vehicles due to their ability to rapidly shift gears, maximizing acceleration and minimizing transmission lag. This translates to a sportier driving experience, crucial for vehicles focused on speed and responsiveness.

- Compact Cars: DCTs are increasingly found in compact cars, aiming to improve fuel economy. The efficiency of the DCT’s gear shifting contributes to the overall fuel efficiency. This balance between performance and economy is a driving factor in their adoption for this vehicle class.

- Luxury Cars: DCTs are frequently incorporated into luxury vehicles to improve the overall driving experience. The smoothness of the shifting process enhances the refinement and prestige associated with these models. The premium feel and performance are valued aspects of this segment.

- Performance SUVs and Crossover Vehicles: DCTs can provide an improved driving experience in these vehicles. The rapid shifting capabilities contribute to a more engaging driving experience compared to traditional automatic transmissions. The balance of off-road capabilities and responsiveness is key in these vehicle classes.

Examples of Car Models Equipped with DCTs

Numerous car models across different segments utilize DCTs. The examples below demonstrate the widespread adoption of this technology.

- Volkswagen Golf GTI: A popular example of a compact car utilizing DCT to deliver responsive acceleration and improved fuel economy. The DCT is a significant feature that contributes to the vehicle’s appeal.

- Porsche 911: This iconic sports car model employs DCTs to optimize performance. The high-performance nature of the vehicle necessitates a rapid and efficient transmission system, making DCT a natural fit.

- Audi A4: This luxury vehicle segment often incorporates DCTs to provide a smooth and refined driving experience. The advanced technology contributes to the overall perception of luxury and sophistication.

- Mazda MX-5 Miata: Even in a sporty roadster, the DCT offers a more engaging driving experience, contributing to the overall enjoyment of the vehicle. The rapid shifting contributes to the responsiveness of the car.

Reasons for Choosing DCTs for Certain Vehicles

Several factors influence the decision to incorporate DCTs into specific vehicles. The need for rapid shifting, efficiency, and refinement plays a crucial role.

- Performance Enhancement: DCTs provide faster gear changes, which translates to improved acceleration and responsiveness, especially critical in sports cars and high-performance models.

- Fuel Efficiency: DCTs, by optimizing gear selection, can lead to better fuel economy, particularly in compact and economy cars.

- Driver Experience: The smooth shifting characteristics of DCTs contribute to a more refined driving experience, which is a key consideration in luxury vehicles.

Performance Implications in Different Vehicle Types

The performance implications of DCTs vary depending on the vehicle type. The responsiveness and smoothness of the shifting are key considerations.

- Sports Cars: DCTs provide a significant performance boost in sports cars, enabling rapid acceleration and precise control. The immediate response and reduced lag are vital for the high-performance driving experience.

- Economy Cars: DCTs can improve fuel economy in economy cars by optimizing gear changes. The efficient operation of the transmission translates to reduced fuel consumption.

Comparison of DCT Usage in Sports Cars and Economy Cars

DCTs are employed differently in sports cars and economy cars, reflecting the varying performance needs.

- Sports Cars: DCTs are chosen in sports cars primarily for their rapid shifting capabilities, maximizing performance and responsiveness.

- Economy Cars: DCTs are utilized in economy cars for improved fuel efficiency. The optimized gear changes contribute to the overall fuel economy of the vehicle.

DCT Design and Construction

Dual-clutch transmissions (DCTs) are complex mechanisms requiring meticulous design and construction to achieve optimal performance. The interplay of multiple components and intricate manufacturing processes contributes to their efficiency and durability. Understanding these aspects provides insight into the technical challenges and innovative solutions employed in DCT development.

Design Approaches for DCTs

Various design approaches are employed in DCT development, each aiming to optimize different aspects of the transmission. Some focus on minimizing friction and wear, others on reducing overall size and weight, and still others on improving shift speed and smoothness. The specific design chosen often depends on the intended application and the vehicle’s overall performance requirements.

Manufacturing Processes in DCT Production

The production of DCTs involves a sophisticated combination of machining, assembly, and quality control procedures. Precise machining of gears, clutches, and other components is crucial to ensure compatibility and optimal performance. Advanced manufacturing techniques, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), are extensively used to ensure accuracy and minimize production errors. Assembly procedures are meticulously designed to ensure correct alignment and secure fastening of all components, further emphasizing the importance of quality control measures throughout the production process.

Materials Used in DCT Construction

The materials employed in DCT construction play a significant role in its performance and durability. High-strength steel alloys are commonly used for gears and shafts, offering a balance between strength and weight. Specialized materials, such as heat-treated steels or composite materials, are employed in specific components where enhanced durability or lightweight properties are needed. The selection of materials depends on the specific application and performance demands of the DCT.

Challenges in Designing and Building a DCT

Several challenges are inherent in designing and building a DCT. Balancing the conflicting demands of efficiency, durability, and compact size is a primary concern. Achieving smooth and rapid gear shifts while minimizing friction and wear in the clutches is another significant hurdle. Ensuring reliable operation across a wide range of operating conditions and environmental factors is crucial, particularly in extreme temperatures.

Further, the precise control and synchronization of multiple components, including clutches and gears, demand sophisticated design and control systems.

Components of a DCT in Hierarchical Structure

The DCT’s intricate design is organized into a hierarchical structure of components.

- Transmission Case: The transmission case is the outermost component that houses all other components. Its design and material selection are critical for strength, durability, and heat dissipation.

- Gearset Assembly: This assembly contains the various gears, shafts, and bearings that facilitate gear changes and power transmission. Proper alignment and precise machining of gears are crucial for optimal performance.

- Clutch Pack Assembly: This assembly includes multiple clutch plates and friction materials for smooth and rapid gear changes. The precise adjustment and synchronization of these components are essential to avoid slippage and ensure smooth shifting.

- Control System: The control system governs the engagement and disengagement of clutches, allowing for seamless shifting. This often involves sophisticated electronic systems that respond to driver inputs and transmission conditions.

DCT Performance and Efficiency

Dual-clutch transmissions (DCTs) are designed to offer a unique blend of performance and efficiency, appealing to drivers seeking both rapid acceleration and fuel economy. Their sophisticated design allows for a smoother and quicker shift sequence compared to traditional automatic transmissions, impacting the overall driving experience.DCTs achieve this through the strategic use of two clutches, enabling rapid gear changes without interrupting power delivery.

This characteristic contributes to a noticeable difference in responsiveness, particularly during acceleration and overtaking maneuvers. The optimized power delivery translates to improved performance, making DCTs a popular choice for vehicles aimed at providing a dynamic driving experience.

Power Delivery Characteristics

DCTs excel in power delivery due to their ability to pre-select the next gear while the vehicle is still in the current gear. This pre-selection avoids the interruption in power flow that traditional automatic transmissions experience during shifts, resulting in smoother acceleration and quicker response times. The precise control over clutch engagement allows for rapid gear changes, minimizing the loss of torque and maintaining a consistent flow of power.

Efficiency Gains

The efficiency gains in DCTs stem from several factors, including the reduced friction losses associated with clutch engagement and disengagement. By pre-selecting the next gear, the transmission avoids the need for simultaneous clutch engagement and disengagement, which are energy-consuming processes in conventional automatic transmissions. This optimized power flow minimizes energy loss, leading to improved fuel efficiency. Additionally, the use of advanced materials and design techniques in DCT components further contributes to enhanced efficiency.

Impact on Fuel Economy

DCTs demonstrably improve fuel economy compared to traditional automatic transmissions. This improvement is largely attributed to the reduced friction and minimized torque interruption during gear changes. Studies have shown that DCTs can achieve a noticeable fuel economy advantage, often ranging from a few percentage points to a more substantial improvement, depending on the vehicle and driving conditions. This translates to reduced operating costs for drivers.

Comparison of DCT Performance Metrics

| Transmission Type | Acceleration Time (0-60 mph) | Fuel Economy (mpg) | Shift Time (seconds) |

|---|---|---|---|

| DCT | 7.5-8.5 seconds | 30-38 mpg | 0.2-0.4 seconds |

| Traditional Automatic | 8.0-9.5 seconds | 28-35 mpg | 0.5-0.8 seconds |

| Manual | 7.0-8.0 seconds | 25-32 mpg | 0.1-0.3 seconds |

Note

* Values are approximate and vary based on vehicle model, engine type, and driving conditions.

Responsiveness in Different Driving Conditions

DCTs demonstrate exceptional responsiveness in various driving conditions. In stop-and-go city traffic, the rapid gear changes contribute to a smooth and efficient driving experience, reducing the feeling of hesitation often associated with traditional automatic transmissions. On the highway, DCTs maintain a consistent power flow, facilitating quick acceleration and overtaking maneuvers, without the noticeable pauses inherent in conventional transmissions.

Moreover, in high-performance applications, the rapid shifts enhance the vehicle’s overall performance.

DCT Maintenance and Repair

Dual-clutch transmissions (DCTs) offer enhanced performance and fuel efficiency but require specialized maintenance and repair procedures. Proper upkeep is crucial for optimal operation and longevity, mitigating potential costly repairs down the line. Neglecting scheduled maintenance can lead to premature wear and tear, resulting in significant expenses and potentially compromising the vehicle’s overall performance.Maintaining a DCT involves a proactive approach, encompassing regular inspections and timely replacements of crucial components.

A well-maintained DCT ensures smooth gear shifts, minimizing wear and tear, and maximizing the transmission’s operational life.

Common Maintenance Procedures

Routine maintenance for DCTs is vital to prevent potential issues. This includes regularly checking fluid levels and condition, ensuring proper lubrication, and adhering to manufacturer-recommended service intervals. These preventative measures significantly extend the life of the transmission.

- Fluid Level and Condition Checks: Regularly inspecting the transmission fluid level and condition is paramount. Low fluid levels or contaminated fluid can lead to premature wear. Checking the fluid’s color and consistency is crucial; dark, gritty fluid signals a need for replacement.

- Filter Replacement: DCTs utilize filters to prevent contaminants from entering the transmission. Replacing these filters at recommended intervals is essential for optimal performance and to maintain the transmission’s efficiency.

- Component Inspections: Visual inspections of critical components, such as clutch packs and actuators, are important. Identifying signs of wear or damage allows for timely intervention, preventing more significant problems.

- Cleaning and Lubrication: Proper cleaning and lubrication of critical components, including sensors and actuators, are essential to prevent sticking and ensure smooth operation. These actions contribute to preventing premature failure.

Troubleshooting Guide for DCT Issues

Identifying the root cause of DCT issues is crucial for effective repair. A systematic approach, involving careful diagnosis and analysis, helps pinpoint the problem and facilitates a cost-effective solution.

- Hesitation or Jerking During Shifts: Hesitation or jerking during gear changes often points to issues with the clutch packs or hydraulic actuators. A thorough inspection of these components and associated fluid levels is necessary.

- Rough or Unresponsive Shifts: Problems with the transmission control unit (TCU) or communication errors between components might cause rough or unresponsive gear shifts. Checking the TCU’s functionality and ensuring proper communication channels are essential.

- Unusual Noises: Uncommon noises, such as grinding or screeching sounds, indicate potential component damage. Identifying the specific location and type of noise helps in isolating the source of the issue.

Steps Involved in Replacing DCT Components

Replacing DCT components requires specialized tools and knowledge. Detailed procedures, including disassembly and reassembly steps, are critical for a successful repair.

- Disassembly: Careful disassembly of the DCT involves removing various components and ensuring proper documentation of the disassembly sequence. This step is crucial for accurate reassembly.

- Component Replacement: Replacing faulty components with new or refurbished parts is essential. This process requires adherence to the manufacturer’s specifications to ensure optimal performance.

- Reassembly: Precise reassembly of the DCT is critical. Following the documented disassembly sequence is essential to ensure proper functionality and prevent future issues.

Tools Required for DCT Maintenance

Specialized tools are often necessary for DCT maintenance. Specific tools and equipment are essential for proper dismantling and reassembly.

- Torque Wrenches: Precise torque application is crucial for ensuring proper assembly and preventing damage to the DCT components. Different torque values are required for different fasteners.

- Specialized Diagnostic Tools: Advanced diagnostic tools are needed for analyzing the DCT’s operation and identifying specific issues. These tools help to analyze fault codes and pinpoint the cause of any problems.

- Hydraulic Press: For certain component replacements, a hydraulic press might be needed. It is essential to use the correct hydraulic pressure for specific parts to avoid damage.

Cost Implications of DCT Maintenance and Repair

The cost of DCT maintenance and repair can vary depending on the specific issues and the required repairs. Factors like labor costs, part prices, and diagnostic procedures influence the overall cost.

- Labor Costs: Specialized technicians are required for DCT repairs. The cost of labor varies based on location and the complexity of the repair.

- Part Prices: DCT components can be expensive. The price of parts depends on the specific components and the manufacturer. Refurbished components might be an alternative, offering a more cost-effective solution.

- Diagnostic Procedures: Using advanced diagnostic tools can help pinpoint the issue and potentially reduce the overall cost of repair.

DCT Reliability and Durability

Dual-clutch transmissions (DCTs) have gained popularity for their performance advantages, but their long-term reliability and durability remain a critical concern for consumers and manufacturers alike. Factors such as component stress, manufacturing tolerances, and driving habits all influence the lifespan of a DCT. Understanding these aspects is crucial for assessing the overall value proposition of a vehicle equipped with this technology.

Long-Term Reliability of DCTs

DCTs, while offering improved performance, are more complex than traditional automatic transmissions. This increased complexity often leads to a higher potential for failure points. The intricate clutch engagement mechanisms and the need for precise synchronization between the clutches contribute to the potential for more frequent maintenance needs compared to simpler automatic transmissions. However, advancements in materials science and manufacturing processes have improved DCT reliability significantly in recent years.

This evolution allows DCTs to handle higher torque and power outputs with greater consistency.

Durability of DCT Components Under Stress

The durability of DCT components is directly linked to the stress they endure during operation. Repeated engagement and disengagement of clutches, coupled with high engine torque, place significant stress on the clutch packs, synchronizers, and the transmission housing. Harsh driving conditions, such as frequent hard acceleration and heavy towing, exacerbate these stresses. Proper material selection and design considerations are crucial to mitigate the risk of premature wear and tear.

Real-World Case Studies of DCT Failure and Repair

Numerous case studies reveal common patterns in DCT failures. These failures frequently involve issues with clutch slippage, premature wear of the clutch packs, and synchronization problems. Specific examples include:

- Clutch slippage, often caused by insufficient lubrication, excessive wear, or improper synchronization, leading to rough shifting and eventual transmission failure. The repair usually involves replacing the faulty clutch pack or even the entire transmission module.

- Gear synchronization issues, potentially stemming from worn synchronizers or improper gear engagement, result in jerky shifts and a decline in performance. Addressing this typically involves replacing the faulty synchronizers or, in severe cases, the entire transmission.

- Transmission housing damage, often a consequence of high impact or stress, might lead to oil leaks or transmission failures. Repair strategies often involve replacing the damaged housing or implementing reinforcement measures.

Examples of DCT Failures and Their Root Causes, Dual clutch transmission

Analyzing the root causes of DCT failures provides valuable insights into potential design flaws and operational considerations. One example involves a vehicle with a history of aggressive driving styles. The DCT experienced premature clutch wear, and the repair necessitated replacing multiple clutch packs. Another case involved a vehicle that was frequently used for towing heavy loads. The transmission housing experienced significant stress, leading to cracking and oil leaks, requiring a complete transmission replacement.

Importance of Regular Maintenance in Preserving DCT Lifespan

Regular maintenance plays a pivotal role in prolonging the lifespan of a DCT. This includes adhering to the manufacturer’s recommended service intervals for oil changes, fluid checks, and inspections. Proactive maintenance, such as monitoring for unusual noises or shifts, can help identify potential issues early on. Prompt addressing of these issues prevents further damage and costly repairs.

Future Trends in DCT Technology

Dual-clutch transmissions (DCTs) are rapidly evolving, driven by the need for enhanced performance, efficiency, and reduced complexity in modern vehicles. These advancements are aimed at addressing evolving consumer demands and industry standards. The future of DCT technology promises exciting innovations, integrating cutting-edge engineering and sophisticated control systems.

Emerging Trends in DCT Technology

DCTs are poised to incorporate several key trends. These trends will influence the design, construction, and overall functionality of future models. This evolution will focus on achieving superior performance, efficiency, and a more refined driving experience.

Potential Advancements in DCT Design and Construction

Future DCT designs will likely emphasize lightweight materials, such as advanced alloys and composites. This will contribute to reduced vehicle weight, enhancing fuel efficiency and acceleration performance. Improved clutch designs, incorporating materials with enhanced friction characteristics and faster engagement/disengagement speeds, are anticipated. Furthermore, advancements in actuator technology will lead to quicker and more precise shifting, resulting in a smoother driving experience.

Integration of DCTs with Other Automotive Technologies

DCTs are expected to seamlessly integrate with other advanced automotive technologies, such as electric powertrains and autonomous driving systems. This integration will lead to improved efficiency and performance, as well as enhanced driving assistance features. DCTs equipped with sophisticated sensors and control systems will optimize shifting strategies in real-time, adjusting to driving conditions and maximizing efficiency. Examples include adaptive shifting algorithms that consider factors like road conditions and driver input.

Evolution of DCTs in the Future

The evolution of DCTs will likely encompass increased automation and reduced driver intervention. Automated shifting algorithms will anticipate driver needs and execute shifts proactively. The integration of electric powertrains with DCTs will yield improvements in overall fuel efficiency and performance, leading to hybrid and fully electric vehicle applications.

Predictions for DCT Technology’s Role in the Automotive Industry

DCT technology is projected to remain a crucial component in the automotive industry, particularly in vehicles demanding high performance and efficiency. The integration of DCTs with advanced powertrains and automated driving systems will play a pivotal role in the development of future vehicles. Examples include the increasing adoption of DCTs in high-performance sports cars and luxury vehicles, reflecting the ongoing demand for refined driving experiences.

The future of DCTs will be intertwined with the broader automotive landscape, with a continued push for higher efficiency and improved performance in vehicles across various segments.

DCT vs. Other Transmission Technologies

Dual-clutch transmissions (DCTs) have emerged as a popular choice in modern vehicles, offering a blend of performance and efficiency. However, they are not the only transmission technology available. Understanding their comparative strengths and weaknesses, along with those of other systems, is crucial for informed decision-making. This section explores DCTs in relation to continuously variable transmissions (CVTs) and automated manual transmissions (AMTs), highlighting key differences and advantages.Comparing DCTs to alternative transmissions reveals a multifaceted picture.

Each technology optimizes for different aspects of vehicle operation, leading to varying performance characteristics. DCTs excel in certain situations, while other transmissions hold advantages in different scenarios. The following sections delve into these comparisons, offering a detailed understanding of each transmission type.

Dual clutch transmissions are known for their smooth shifting, but maintaining their performance often involves more than just regular servicing. A key part of keeping these transmissions in tip-top shape is applying a quality ceramic coating, like the ones offered at ceramic coating , to protect the critical components from wear and tear. This enhanced protection, in turn, results in a more reliable and responsive dual clutch transmission over time.

Comparison with Continuously Variable Transmissions (CVTs)

CVTs, characterized by a continuously variable ratio between engine speed and wheel speed, offer a smooth and seamless power delivery. This smooth operation translates to a generally quiet and comfortable driving experience. However, the inherent lack of discrete gear ratios in CVTs can sometimes result in a perceived loss of responsiveness, particularly during acceleration. The efficiency characteristics of CVTs can vary, with some models showing significant potential in fuel economy.

DCTs, conversely, offer precise gear changes and, depending on the design, can outperform CVTs in terms of acceleration and performance.

Comparison with Automated Manual Transmissions (AMTs)

Automated manual transmissions (AMTs) are a simpler and often more affordable alternative to DCTs. Their operation typically involves a clutch and a traditional manual gearbox, automated via actuators. AMTs offer some advantages in terms of cost and simplicity, and they often retain a degree of the engaging feel associated with manual transmissions. However, AMTs often experience jerky shifts and reduced fuel efficiency compared to DCTs.

The complexity of the clutch system can also lead to higher maintenance costs over time. DCTs generally provide smoother shifts and superior performance characteristics, particularly in acceleration.

Operating Principles and Differences

DCTs utilize two clutches and two gear sets to provide rapid gear changes. This dual-clutch system enables the transmission to select the next gear while the engine continues to provide power. This allows for seamless transitions and efficient use of power. CVTs, in contrast, use a continuously variable belt or pulley system to change the gear ratio.

This system results in a smooth and continuous power delivery but with a loss of discrete gear steps. AMTs use a clutch and a traditional manual gearbox, with the actuation of the clutch and gear shifting being automated.

Comparative Table of Transmission Types

| Transmission Type | Operating Principle | Advantages | Disadvantages |

|---|---|---|---|

| Dual Clutch Transmission (DCT) | Two clutches, two gear sets for rapid gear changes | Quick acceleration, smooth shifting, potentially better fuel economy than AMTs | Higher initial cost, more complex design |

| Continuously Variable Transmission (CVT) | Continuously variable ratio between engine and wheel speed | Smooth operation, potentially good fuel economy | Reduced responsiveness during acceleration, less precise gear selection |

| Automated Manual Transmission (AMT) | Automated clutch and manual gearbox | Lower cost, simpler design, some feel of manual transmission | Jerky shifts, potentially lower fuel economy compared to DCTs |

Illustrative Examples of DCT Systems

Dual-clutch transmissions (DCTs) are increasingly common in various vehicle types, showcasing a range of design implementations. Understanding these examples helps appreciate the versatility and adaptability of this technology across different applications. This section explores different DCT architectures and their key characteristics.Different manufacturers employ variations in DCT design, often tailoring the system to the specific performance requirements of the vehicle.

This leads to a variety of implementations, each optimized for a particular set of conditions. These differences are crucial for understanding the adaptability and performance potential of DCTs.

Specific DCT System Examples

Several DCT systems have emerged, each with its own approach to achieving optimal performance and efficiency.

- Volkswagen’s DQ200: This is a popular example of a DCT, known for its smooth gear changes and relatively compact design. It is frequently used in smaller and mid-sized vehicles, emphasizing efficiency and everyday driving comfort. Its robust design caters to a wide range of driving conditions, contributing to its widespread adoption.

- Porsche’s PDK: A sophisticated DCT system, the PDK is often associated with high-performance vehicles. Its design emphasizes precise gear shifting, providing a sporty driving experience while maintaining high levels of efficiency. The PDK’s focus on rapid and precise shifting makes it suitable for high-performance applications, particularly in sports cars.

- Other DCT Implementations: Various other manufacturers have developed DCTs with unique features, including improvements in clutch actuation and gear shifting algorithms. These innovations reflect a continuous drive to enhance performance and efficiency in the DCT design space. Specifics often depend on the particular vehicle application, with some systems emphasizing fuel economy and others focusing on performance. These modifications cater to diverse automotive demands.

DCT System Architecture

A typical DCT system comprises multiple components working in concert to provide seamless gear changes. The coordination between these elements is critical for the efficiency and smoothness of the transmission. This structured approach allows for precise and responsive shifting.

| Component | Description |

|---|---|

| Clutch Pack 1 | Handles odd-numbered gears (1, 3, 5, etc.). |

| Clutch Pack 2 | Handles even-numbered gears (2, 4, 6, etc.). |

| Gear Set | A set of gears designed for smooth and rapid gear transitions. |

| Control Unit | Manages the engagement and disengagement of clutches to facilitate gear shifts. |

| Hydraulic Actuators | Control the pressure applied to the clutches. |

DCT Operational Flow

The operation of a DCT involves a sequential process of clutch engagement and disengagement, as depicted in the following flow chart:

- Gear Selection: The driver selects the desired gear.

- Clutch Engagement: The control unit activates the appropriate clutch pack based on the selected gear.

- Gear Transition: The clutch pack engages the corresponding gear set.

- Clutch Disengagement: The control unit disengages the clutch previously engaged, preparing for the next gear change.

- Gear Change Complete: The process repeats for the next gear shift.

DCT Component Diagram

A detailed diagram illustrating the components of a DCT system can be visualized as follows:

[Imagine a simplified diagram here. A diagram would show the engine connected to two clutch packs (one for odd gears, one for even gears). These packs connect to a gear set. The control unit, actuators, and sensors would be shown as separate components influencing the operation of the clutches and gears.]

The diagram would highlight the interconnected nature of the components, emphasizing the precise coordination required for smooth operation. The layout shows how each component contributes to the overall functionality of the transmission.

User Guide to Understanding DCT Technology

A user-friendly guide to understanding DCT technology can be created through clear and concise explanations. The guide can include:

- Basic Principles: Explaining the dual-clutch mechanism and how it enables rapid gear changes.

- Advantages and Disadvantages: Highlighting the benefits of DCTs (such as fuel efficiency and performance) and acknowledging any potential drawbacks (such as higher initial cost).

- Real-World Applications: Demonstrating how DCTs are used in different vehicle types and highlighting the benefits in each case.

- Maintenance Tips: Providing simple maintenance tips for optimal DCT performance.

Closure: Dual Clutch Transmission

In conclusion, dual clutch transmissions represent a significant advancement in automotive technology. Their unique characteristics, including rapid gear changes and enhanced fuel efficiency, make them attractive for a variety of vehicles. While they may require a higher initial investment and specific maintenance procedures, the overall performance benefits often justify the cost for drivers seeking a powerful and responsive driving experience.

Question & Answer Hub

What are the common maintenance procedures for DCTs?

Regular fluid checks and replacements are crucial. Properly maintaining the clutch packs is also essential. Consult your vehicle’s owner’s manual for specific maintenance schedules and procedures.

What are some common issues with DCTs?

Slipping clutches, rough shifting, and unusual noises are some potential issues. Prompt diagnosis and repair are vital to avoid further damage and costly repairs.

How does DCT compare to a CVT?

DCTs offer more precise gear changes and a sportier driving experience. CVTs offer a smoother transition, but can sometimes feel less responsive.

What are the environmental impacts of DCTs?

DCTs are generally efficient, often improving fuel economy compared to traditional automatic transmissions. However, the manufacturing process and overall environmental impact of the vehicle need to be considered.